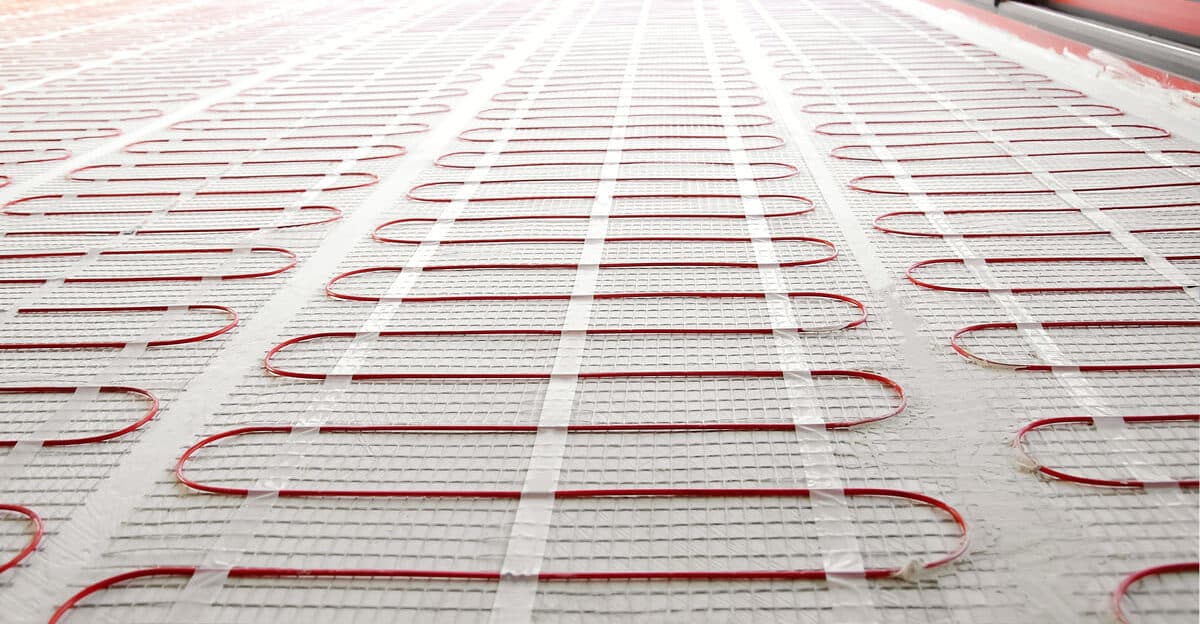

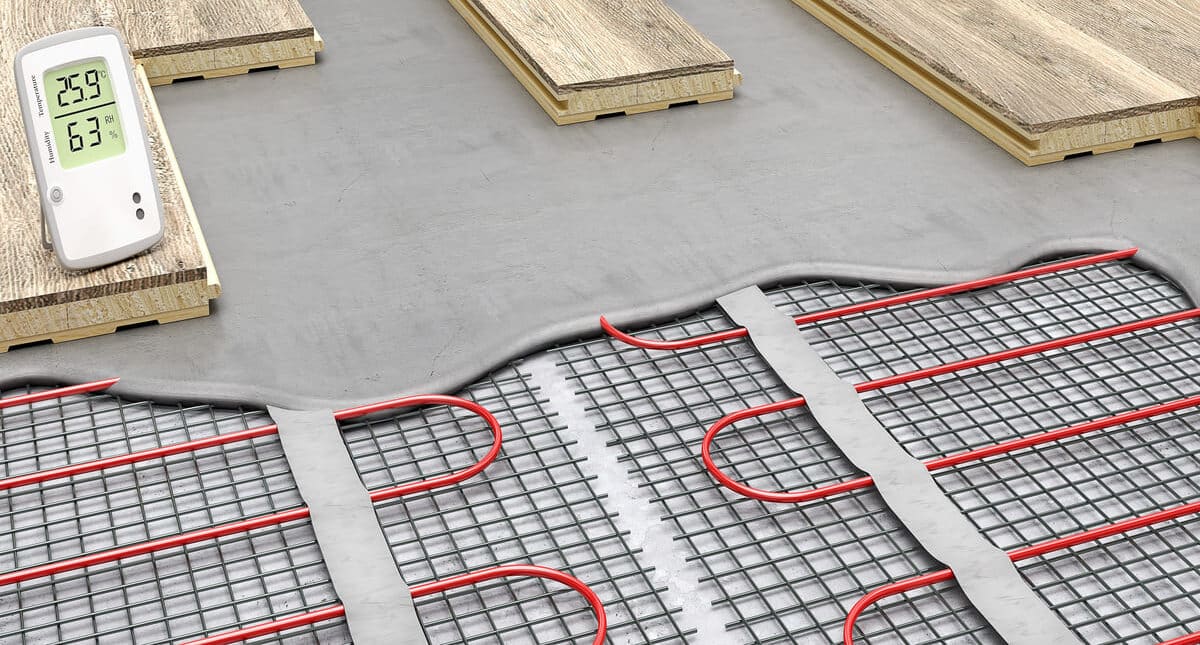

When it comes to choosing the best underfloor heating system for engineered wood flooring, there are two main options – electric and water-based. Electric UFH systems require wiring beneath the flooring, while water-based UFH uses pipes with hot water running through them. Both systems provide efficient heat distribution and comfort but they have their own unique pros and cons.

Electric UFH is a cost effective option as it requires less installation time and can be powered by a low voltage circuit. However, electric UFH tends to be less powerful than water-based systems and can struggle to meet high heat requirements in large spaces.

Engineered wood flooring is an ideal choice when considering underfloor heating, as it offers many advantages. It has superior thermal conductivity compared to solid wood flooring, meaning heat will be more evenly distributed across the room. Additionally, engineered wood floors are usually thinner than solid wood which helps to reduce the amount of heat loss that can occur. On the downside, it is important to make sure that engineered wood flooring is properly acclimatised before installation over a UFH system, as too much moisture can cause warping or cracking. Furthermore, careful consideration should be given to insulation in order to prevent unnecessary energy wastage from occurring.

When installing underfloor heating with engineered wood flooring, several factors must be taken into account. Thermal conductivity of the floor should be considered, as well as its thickness and the limits of heat transfer. Additionally, it is important to ensure that the moisture content and humidity of the engineered wood remain within a safe range for use with UFH systems. The temperature limitation of wooden flooring should also be factored in when deciding on an appropriate system. Lastly, it is essential to consider the importance of insulation in order to protect both your UFH system and your floors from damage.

Before installing an engineered wood floor, it is important to allow the flooring to acclimatise. This process helps the wooden planks adjust to the humidity and temperature of the room, reducing movement once laid and helping prevent damage. The timber should be left in its packaging for a minimum of 48 hours at normal room temperature, allowing it to adapt before being installed. It is also essential that any existing heating system or air conditioning is turned off during this period as sudden changes in temperatures can cause swelling or shrinkage of the planks which could lead to warping.

The thermal conductivity of engineered wood flooring is an important factor when installing underfloor heating. Poor thermal conductivity can lead to inadequate heat distribution and inefficient use of energy, resulting in increased running costs. It’s essential that the wooden floor you choose has a high level of thermal conductivity to ensure the best results from your UFH system. When choosing an engineered wood floor for UFH installation, make sure it has a higher than average rating for thermal conductivity. This will help to maximise the efficiency of your system and minimise energy consumption over time.

When installing underfloor heating with engineered wood flooring, the thickness of the floor is an important factor to consider. Too thick a floor can reduce heat transfer and limit the efficiency of your system, while too thin a floor can cause it to overheat. The optimal floor thickness for underfloor heating is usually between 18mm-22mm. Kiln dried timber is recommended as this will provide better insulation and help to prevent warping or shrinking when heated.

There are limits to the amount of heat that can be transferred. This is due to a combination of factors, such as the thermal conductivity of engineered wood floors, the thickness of the floor and its moisture content. As wooden flooring can expand or contract in response to changes in temperature and humidity, it’s important to consider these limits when planning your UFH system. The temperature limitation for engineered oak flooring should not exceed 27°C while maximum temperatures for wooden flooring generally range between 24-27°C. Insulation is also essential in order to ensure an even spread of heat throughout the room.

We Are Also Available to Offer Heat Pumps Related Advice

To find out more about our services, get free quotations, or arrange an appointment, call this number 0204 586 6171.